I recently attended a small workshop of Eastern style paper making at Pulp & Deckle, featuring Japanese mulberry (kozo), Japanese gampi, and Philippine gampi. There was also an experimental mix of wheat grass and kozo, which isn't foldable, but pretty cool looking.

Left to Right: Three sheets of Philippine gampi, 11x17"; one sheet of wheat grass with kozo; one sheet of kozo and Japanese gampi blend, 8.5x11"; two sheets of kozo, 8.5x11".

Forming the sheets took a couple tries to get approximately correct. A few of the sheets that I made turned out quite well. The nicest sheet was the kozo/gampi blend, which was a pretty even distribution of fiber with a nice texture.

The paper was quite responsive to the folding, though was a tad too thick to go much further in detail level at this size. I can't wait to be able to start making most, if not all, of my origami paper, because there will be great potential in creating texture and color. Just need to figure out the right methodology for forming very large sheets (at least 28x40", to match the sheets I use for lamps). Anyway, here's the little doodle I made with that sheet.

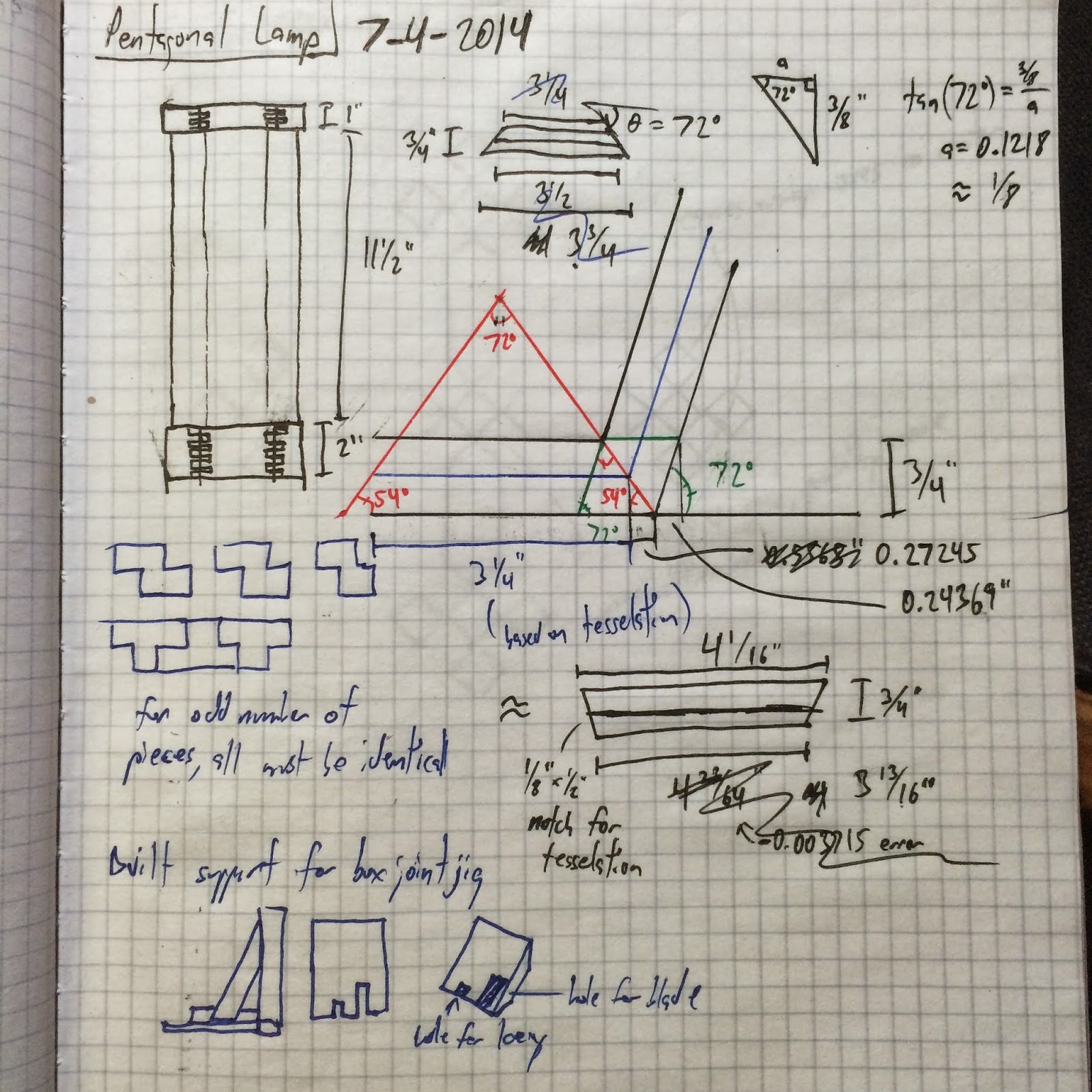

Front of Pattern

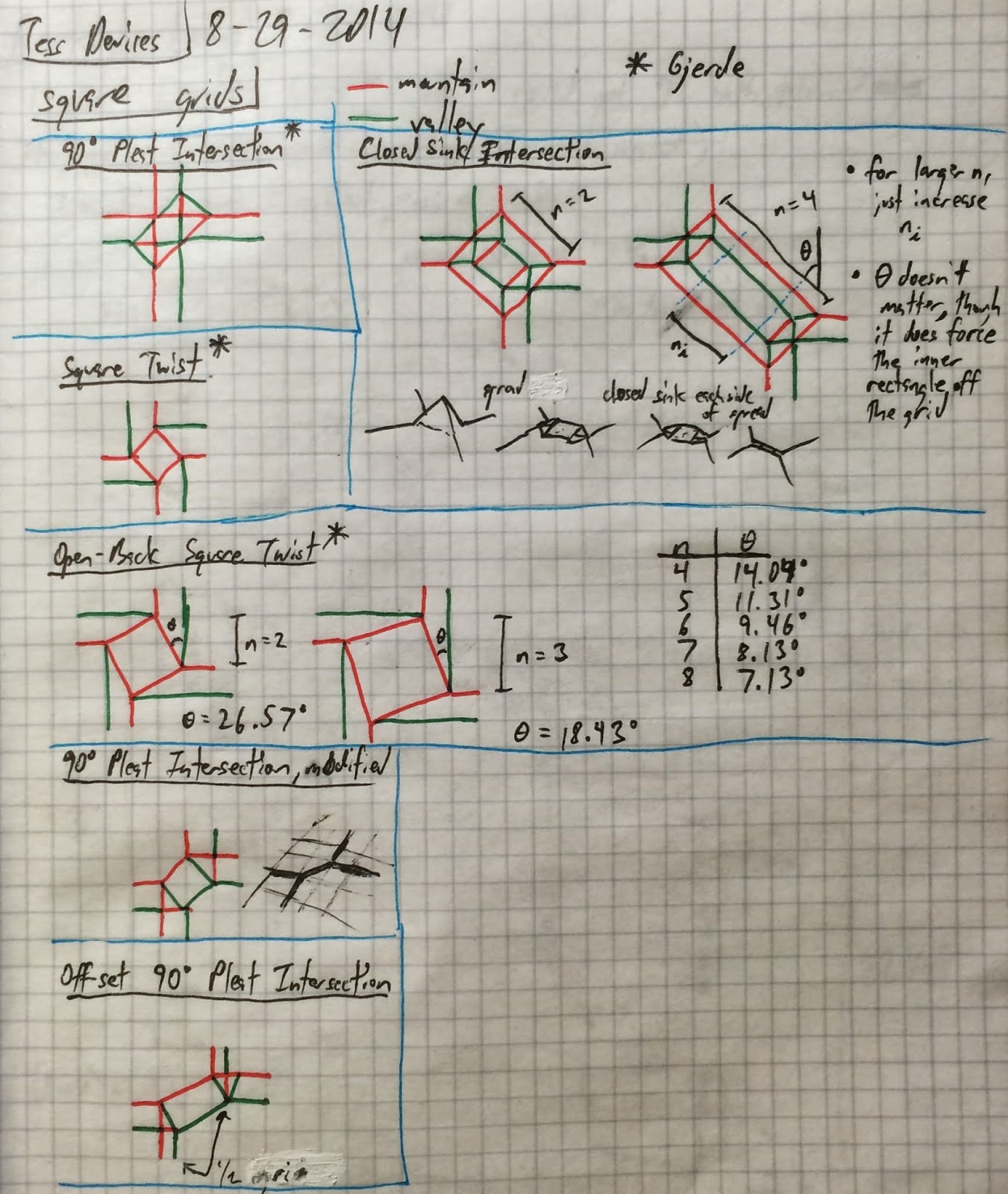

Back of Pattern